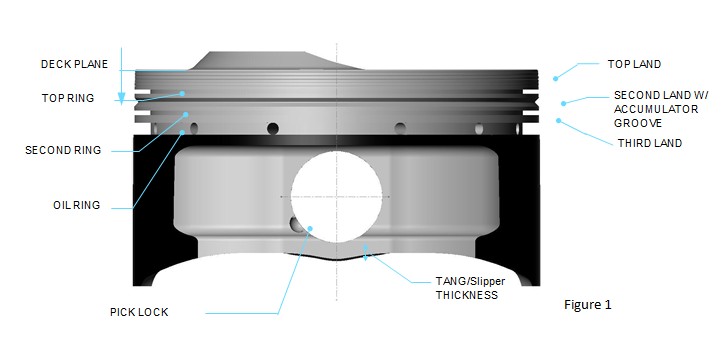

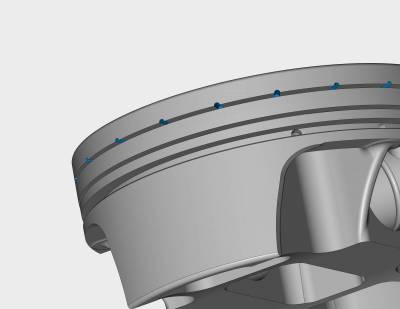

See figure 1. Assuming your top and second rings are of different thicknesses you can simply measureyour rings and compare them to the groove dimensions. (SEE DRAWING) In instances where the top and second rings are of the same thickness the top ring will generally be of a shiny silver/copper color whereas the second ring will be of a dark grey or black coloring. Both rings will normally be marked with a dot(.), number, or letter that will aid in determining which side of the ring will face up toward the dome of the piston.

If the rings don’t have a dot or letter to mark “up”, check the ID of the ring and they should be beveled. The inner beveled edge of the top ring will face up towards the cylinder head, and the inner beveled edge of the second ring will face down towards the crank.

Additionally, some second rings will have a tapered hook groove on the OD. This hooked edge will face downward as its function is to scrape oil back down into the crank case. See Figure 4

In the rare instance that you receive a ring with no designation, though it could mean the ring manufacturer has determined that it will work effectively either way, we recommend that you contact us for clarification.

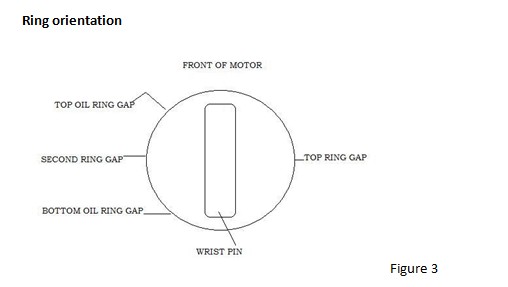

All of our oil rings for 4-stroke applications utilize a 3-piece design which consists of two thin oil rings separated by an expander (wavy) ring.

PLEASE NOTE: DO NOT ALTER YOUR EXPANDER. Oil ring gap specifications are for the top and bottom rails only! Oil ring expanders are designed to butt against each other and when installed along with the rails allow the ring to have the correct tension when seated in the cylinder.

You may also have a piston that requires the use of a rail support, that rail will have a dimple to prevent rotation.