Heavy stronger piston design is not always best for performance optimization

When buying turbo pistons or upgrading piston pins, heavier is not always better. “If I have a turbo, better just buy the strongest, heaviest piston and pin they have and then I’m covered for anything, right?” Although you do want strong enough parts for the power and usage that you have planned, what we are finding is that too many times customers are over-buying for their builds and actually causing premature wear, loss of power and revs, and spending more when they could have used the money elsewhere. Here, I would like to explain why purchasing heavy duty pistons or upgrading pins good for 1600HP when you are only ever going to see 800HP can actually be a bad thing.

When buying turbo pistons or upgrading piston pins, heavier is not always better. “If I have a turbo, better just buy the strongest, heaviest piston and pin they have and then I’m covered for anything, right?” Although you do want strong enough parts for the power and usage that you have planned, what we are finding is that too many times customers are over-buying for their builds and actually causing premature wear, loss of power and revs, and spending more when they could have used the money elsewhere. Here, I would like to explain why purchasing heavy duty pistons or upgrading pins good for 1600HP when you are only ever going to see 800HP can actually be a bad thing.

1) Crank balancing. Heavy piston assembly (piston, pin, locks, and rings all weighed together) = more weight must be added to the crank to run properly.

2) Can limit max RPM and slow rev speed. At RPM, grams turn into pounds. Imagine those extra pounds of weight your crankshaft is trying to rotate, it can not only limit the rev speed of your engine and peak power/RPM, but put extra stress on other components.

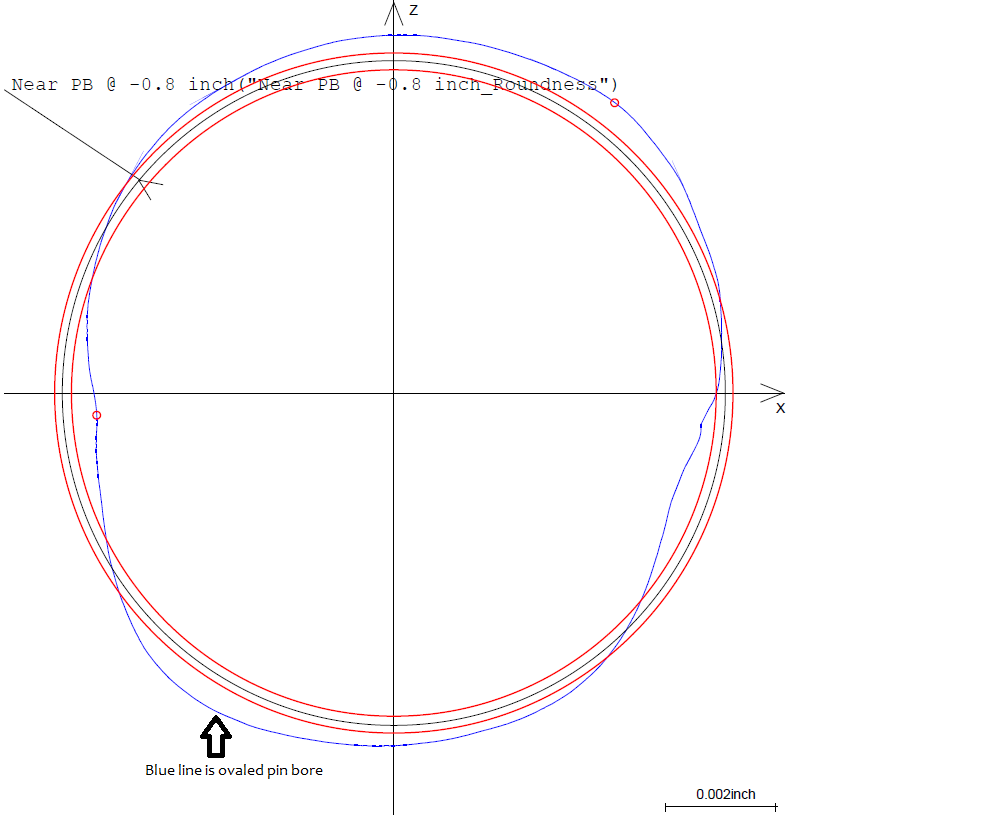

3) Stress and wear on the pin bores. Although detonation and insufficient oil getting to the pins are also causes, extra heavy pins in the piston can also oval out the pin bores over time. Problems with ovaling out pin bores include the clearance continues to increase and can eventually fatigue the pin boss area and initiate cracks, or in bad cases it can pop a wire lock out and the pins walk out the door. When we design a piston for a high HP and/or RPM, we keep extra material in the pin boss for more pin engagement, and we also add more material and design underneath the pin bore in what is called the tang, or slipper to support more weight and stresses.

4) Stress and wear on rods and rod bearings. Rods not only need to be designed for your max HP, max RPM, and all the drifting, drag racing, or endurance road racing abuse that you have in store for it, but also for the force loads that piston attached to it is going to enact. Think about shoulder pressing a dumbbell, more weight equates to fewer reps and quicker fatigue (unless maybe you’re The Rock) Same goes for the rod bearings. Yes, that tiny sliver of metal between the connecting rod big end and your crankshaft has to support all the weight of everything on top of it. Any weight you can take off the rotating assembly helps the bearings last longer.

5) Extra clearances where it may not be needed. Heavier duty pistons can use looser clearances to allow for the high cylinder pressures and heat from large turbos. If you install these kinds of parts with the clearances they are recommending in an engine not seeing those same pressures, you may end up with some piston slap, louder cold starts, and/or potentially higher skirt and cylinder wear.

6) Extra Cost. Often with “high horsepower upgrades” comes a higher price tag. All this is not to say that people should not be upgrading to stronger piston designs and stronger pins when needed.

But with this knowledge you can hopefully avoid purchasing a piston and/or pin that is just not right for your build. Where another manufacturer may want to just sell you every expensive upgrade they have, at CP-Carrillo we want to ensure you are getting the perfect product for your build. So where do you go from here? The first question you should ask is “What is the max horsepower you want to achieve with your build?” But also try to be realistic. If everyone else is making 600hp with the turbo you just bought, don’t ask for a 1200hp piston assembly. CP-Carrillo offers an HD line of many popular engines including: Honda B-series and K-series, Toyota 2JZ, Nissan GTR, and Mitsubishi 4G63, but these pistons were designed for about 225-350hp PER CYLINDER, so they are quite heavy. However I would not recommend these to someone making low boost because of all the reasons above. Regarding pins, be careful not getting a super thick pin if you don’t need it. We are happy to recommend a pin to you based on your power goals. We offer numerous thicknesses and multiple upgraded materials depending on your needs. Contrarily, if you are making big power, you can also check to make sure the pins supplied with your parts are sufficient for your goals. When in doubt, best to check it out.

#themoreyouknow #cpcarrillo #cppistons #pistons #pins #heavyduty #weightmatters #performance #engineering