Bolt Stretch vs. Torque?

At CP-Carrillo we are asked constantly what the assembly torque specification for our bolts is.

While torque is a relatively easy and fast way to assemble non-critical engine components, a higher degree of precision is required when assembling a connecting rod.

When assembling a connecting rod we are not merely putting two pieces of metal together, no there is much more going on. Specifically there are two things we are focused on; bearing crush and clamp load. Correct bearing crush is achieved when sufficient clamp load is applied. If too little clamp load is applied the big end bore of the connecting rod can distort and cause premature bearing or bolt failure.

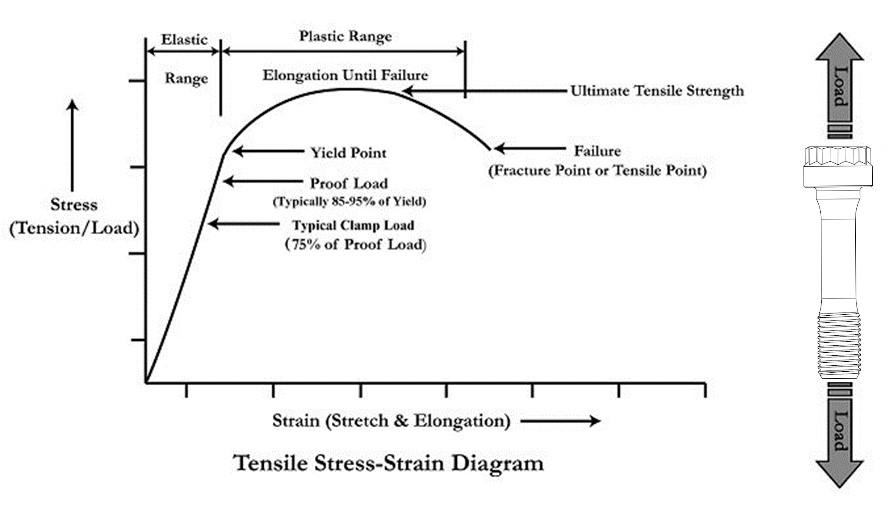

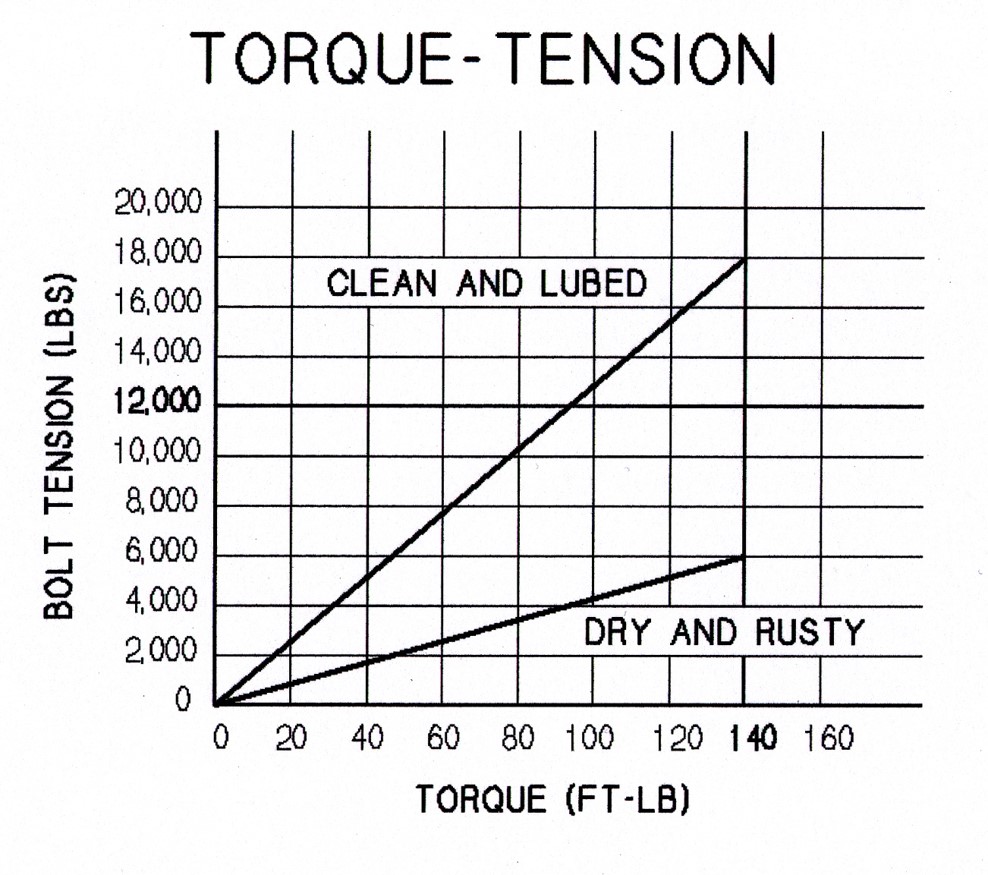

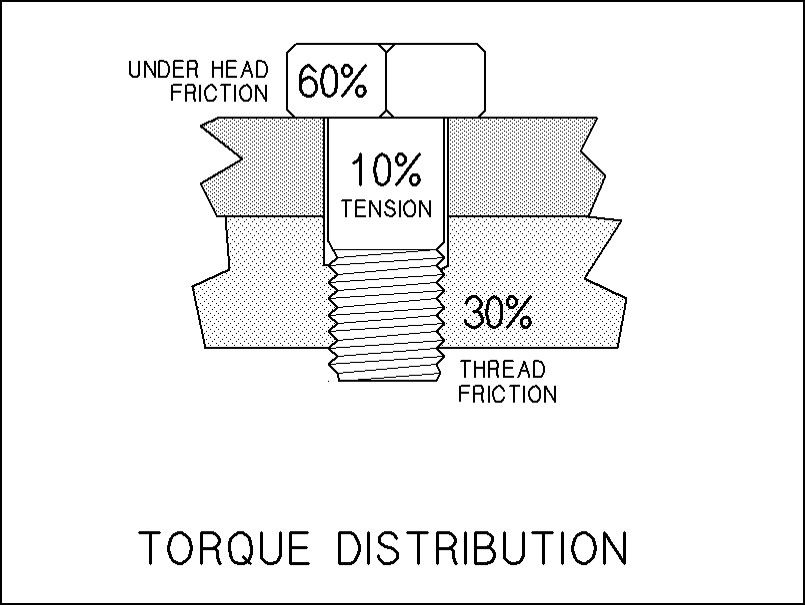

So with clamp load being so important how do we insure that proper clamp load is applied? The answer is stretch. At this point many people would say “hold on there, because doesn’t torque tighten enough?” Most of the torque applied to a fastener is absorbed overcoming friction forces in the threads and the surface area under the fastener head. This results in a accuracy of +/-25% and depending on lubricate and cleanliness can be far worse. Tightening a fastener through elongation (stretch) results in a much more satisfactory +/-3% accuracy.

So why do we need to be so accurate? To achieve the maximum clamp load we need to stretch the bolt to its proof load. If we stretch the bolt too much we both yield the bolt and distort the bore housing, too little and we do not achieve enough clamp load to keep the split line of the connecting rod closed under engine loads. Always refer to the Carrillo bolt instruction sheet when determining how much stretch to apply to your bolts.

Remember torque is for burning rubber, not your bolts!