Hard Anodizing

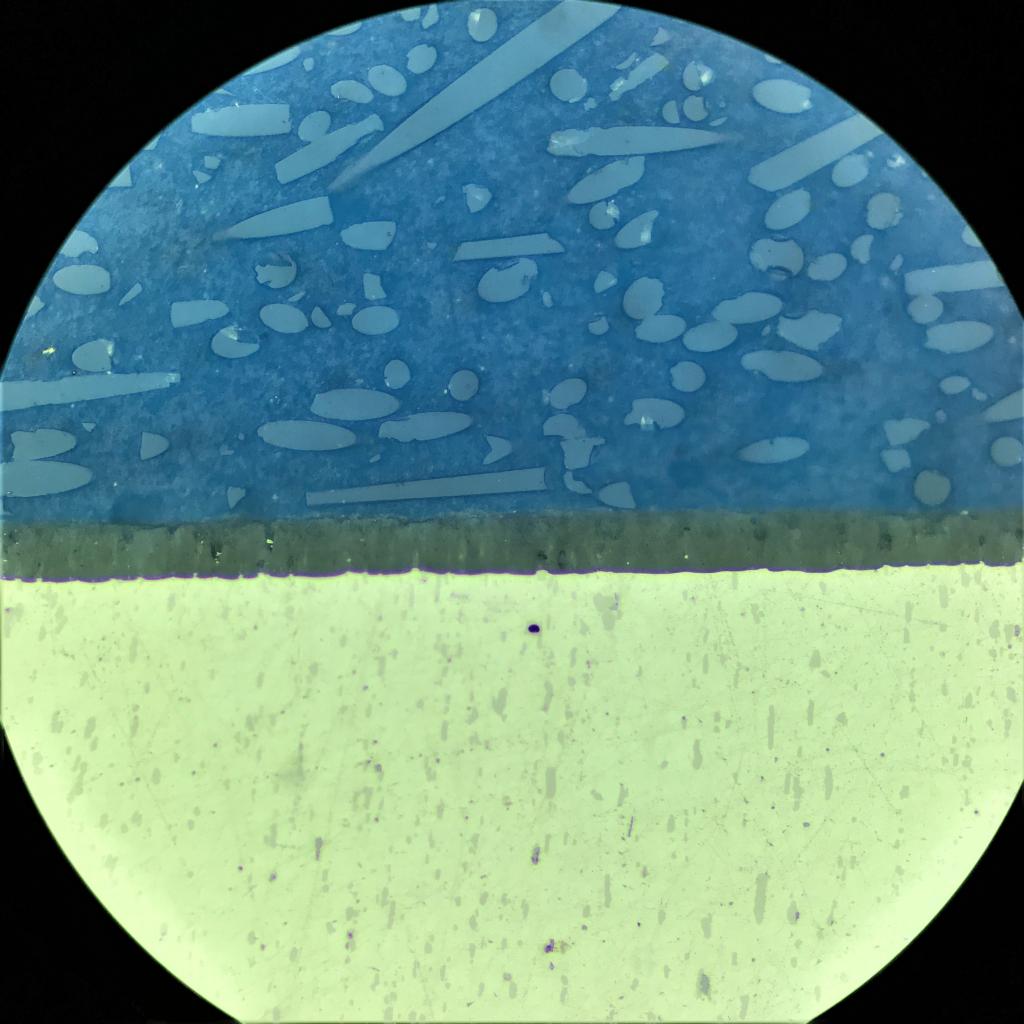

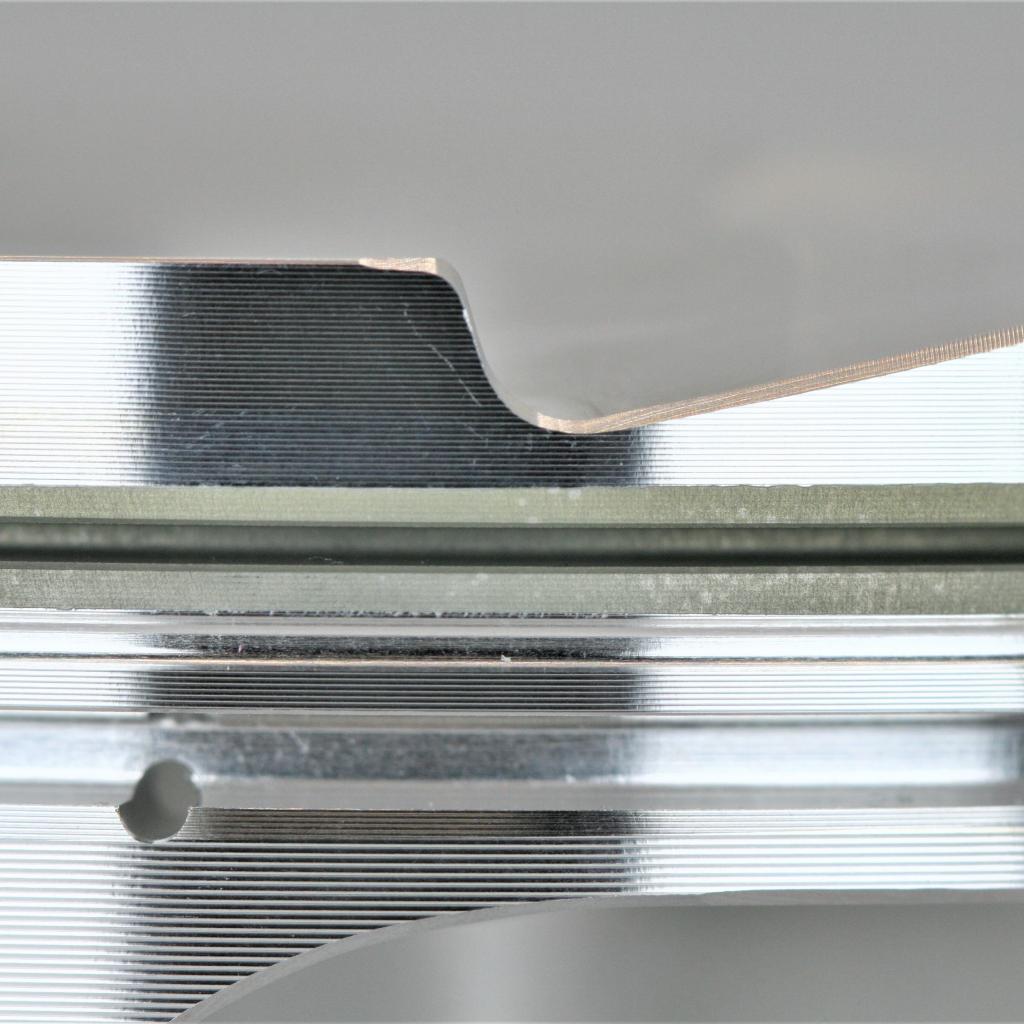

Did you know that Hard andodizing is not traditional coating? Nothing gets added, sprayed or baked onto the part. Nothing can peel or chip. Anodizing is created by converting the surface aluminum into aluminum oxide. This forms an extremely durable, hard, abrasion resistant and long lasting layer. The process is called anodizing because the piston being treated forms the anode of an electrolytic cell. Parts are surrounded by sulfuric acid and exposed to a relatively low – voltage DC current. Most of our OEM pistons get Type III hard anodized inside the compression ring groove for wear resistance. All of our top fuel pistons are entirely Type III anodized to withstand the abuse in the most extreme form of racing.