How to measure and set proper ring end gap for your pistons

Piston ring end gap is just as critical as your bearing clearances but is often overlooked. Just because the ring manufacture says the rings are for a certain bore size it is ultimately the responsibility of the builder to verify the proper end gap. The end gap will vary by application, you would not want the wider gaps used in high boost applications for your street car. This could create a situation where the combustion gasses are allowed past the rings thus causing power loss. Conversely having an end gap that is too tight will cause the ring to butt together, this is devastating to Your engine and will cause piston failure and premature wear. Piston rings are a vital component to any Engine and should be treated with the same care and attention as every other piece in the rotating assembly.

The recommended measuring procedure is as follows:

- A torque plate should be installed on the engine (if applicable) and torqued to the same specification as the cylinder head.

- Piston ring should be placed below and square to the deck.

- Measure ring end gap with a feeler gauge.

** If ring gap is less than the minimum specified for your bore size and application it will be necessary to file fit the rings.

File Fitting Procedures:

- Ring gap must be filed using a ring filing tool. (Available online or at your favorite parts house)

- Always file the rings in an inward direction making sure the ring is square to the sides.

- Always finish the filing by hand using a fine file to break any burrs around the face and tops of the ring.

**Important: ring sets are made for specific bores, for every .001” over the intended bore size, ring gap will increase by .00314”

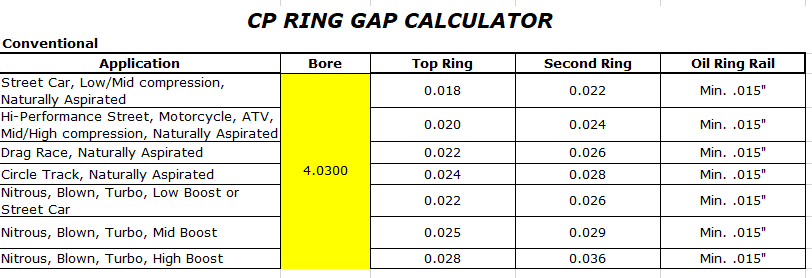

Here is a common bore size with the recommended minimums.