Inertia Loading in Connecting Rods: How Stroke, RPM, and Piston Weight Impact Durability

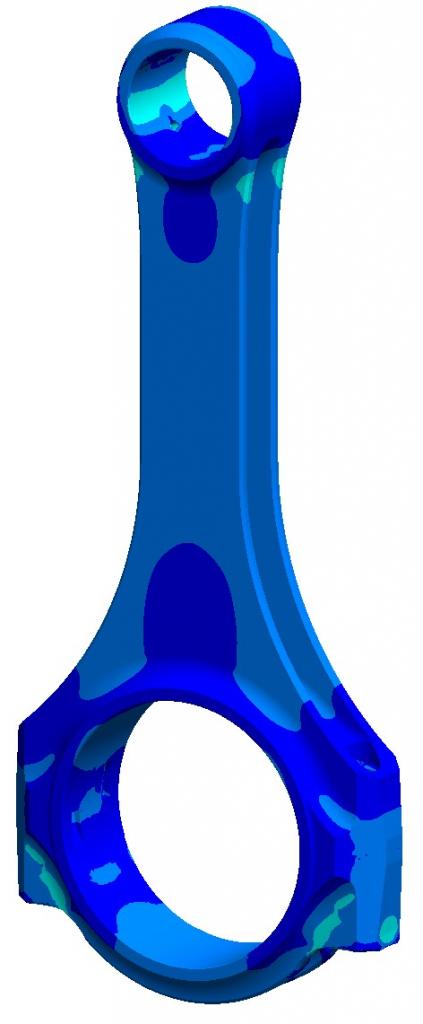

Inertia Loading on a Connecting Rod

Inertia loading is determined by a combination of stroke, rod length, piston and rod assembly weight, and RPM. Inertia represents the force trying to pull the connecting rod apart at the split line. If the rod bolts do not provide sufficient clamp load, this force can either separate the cap from the rod or even pull the pin out of the small end.

The factors that increase inertia load are:

-

Higher RPM

-

Heavier piston assemblies

-

Unfavorable rod/stroke ratios

To illustrate:

-

Reducing stroke from 4.250” to 3.250” decreases inertia load by about 27%.

-

Reducing piston weight from 640 g to 540 g decreases load by about 10%.

-

Lowering max RPM from 9000 to 8000 decreases load by about 21%.

This is why we ask for detailed information when designing your connecting rod—we evaluate everything the rod will be required to handle. Even what may seem like a minor change can significantly affect inertia loads and overall durability.

When specifying your rod, always provide two key RPM values:

-

Maximum RPM – for inertia load calculations.

-

RPM at maximum horsepower – for compressive load analysis.

#themoreyouknow #cpcarrillo # carrillorods #conrods #inertia #design #performance #rpm #hp #compressiveloading