Rings

- What is the difference between CP-CARRILLO and BULLET Series Pistons?

- What do we recommend for Ring Honing?

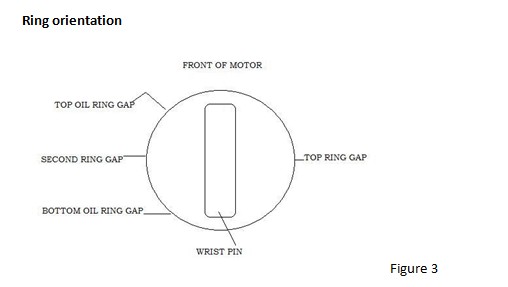

- Ring orientation

- Ring end gaps

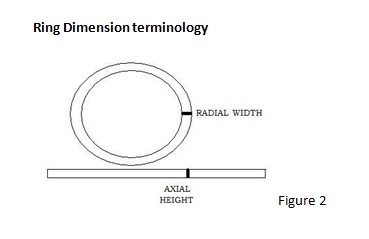

- Ring Dimension terminology

- My ring pack has 3 rings, but my piston only has 2 ring grooves. Did I get the wrong ring pack? Or was the piston made incorrectly?

- I broke a ring during the install, can I just use OEM rings with this piston?

- How do I identify Tops, 2nds and oil rings?

- How do I cut ring grooves?

Q: What is the difference between CP-CARRILLO and BULLET Series Pistons?

Both CP-CARRILLO and BULLET are high quality forged pistons, made from 2618-T61 Alloy. CP-Carrillo pistons are designed for high performance racing engines and are available for many "race specific" applications. Additionally, CP-Carrillo can be custom made in as little as 3 days to your specification. BULLET Series Pistons are large production runs on centralized manufacturing cells made from dedicated “Bullet” forgings. An application specific forging, as well as manufacturing in larger quantities reduces machining time. We pass the savings on to you, offering a more economically priced part, made on the same machines as a traditional CP!

In addition, the BULLET Series features a quality 1.2mm, 1.5mm, 3.0mm ring package and includes Chromoloy wrist pins with wirelocks. The 1.2mm carbon steel nitrided top ring is extremely durable and offers reduced friction over 1.5mm and 1/16" top rings. A 1.5mm Napier (hooked face) 2nd ring is used to improve oil control over conventional taper-faced rings.

Q: What do we recommend for Ring Honing?

For use with our CPN and CPN2 piston rings, we recommend plateau honing with a cylinder bore cross hatch angle

of 35-40 degrees.>/p>

To reach this roughness, the manufacturers of honing machines and accessories recommend using for a gray cast iron engine block and Nikasil cylinders.

- Conventional stones #220 - #280 grit or

- Diamond stones #325 - #550 grit

After honing with either the conventional or diamond stone, the same manufacturers suggest to finish your honing by smoothing the surface with a fine grit conventional abrasive (#400 - #600 grit) or to sweep the bores with a flexible brush or a nylon bristle plateau honing tool. This is necessary to get rid of jagged peaks and folded or torn material.

Important Notice

Important Notice

Be sure to confirm with your honing equipment manufacturer that the recommended stone grit will produce the following Rz and Ra roughness recommendations.

Rz = 59 - 138 µ in [=1.5 – 3.5 µm] or Ra = 15 - 35 µ in [=0.4 – 0.9 µm]Please click here to download "Cylinder Honing Recommendations" (pdf - 71KB)

The following are guidelines for ring installation. Certain applications may require different clearances. Consult the enclosed charts and diagrams before installing rings.

Please click here to download "Ring Installation Instructions" (pdf - 300KB)

Q: Ring end gaps

Due to the wide variance of expansion rates typical of power adders (nitrous, turbos, etc.), air cooled versus water cooled, marine applications, etc., it can be difficult or impossible to give ring end gap recommendations that will be accurate across the board. Please be aware that the information provided is only a guideline and that any concerns should be addressed with your engine builder. All information is provided in inches of ring gap per inch of bore. EXAMPLE: A recommended ring gap of .0040 per inch on a motor with a 4.000 inch bore would yield a ring end gap of .016 inches as .0040 x 4.000 = .016

DOMESTIC AUTOMOTIVE: Normally Aspirated (no power adders) up to 600hp.

- Top Ring = .0045 - .0050 per inch of bore

- Second Ring = .0050 -.0055

- Oil Rings – Actual gap = .015-.050

DOMESTIC AUTOMOTIVE: Normally Aspirated over 600hp and turbo/nitrous applications below 750hp.

- Top Ring = .0050 - .0055

- Second Ring = .0055 - .0060

- Oil Rings – Actual Gap = .015 -.050

DOMESTIC AUTOMOTIVE: Turbo/Nitrous applications above 750hp.

- Top Ring = .0060 - .0070

- Second Ring = .0070 - .0080

- Oil Ring – Actual Gap = .015 - .050

SPORT COMPACT: Normally Aspirated to 300hp

- Top Ring = .0040 - .0050

- Second Ring = .0045 - .0055

- Oil Ring – Actual Gap = .015 -.050

SPORT COMPACT: Turbo/Nitrous applications to 450 - 750hp

- Top Ring = .0050 - .0055

- Second Ring = .0055 - .0060

- Oil Ring – Actual Gap = .015 - .050

POWERSPORTS: Normally Aspirated

- Top Ring = .0040 -.0045

- Second Ring = .0045 - .0050

- Oil Ring – Actual Gap = .015 - .050

POWERSPORTS: Turbo/Nitrous applications

- Top Ring = .0045 - .0050

- Second Ring = .0050-.0055

- Oil Ring – Actual Gap = .015 -.050

Q: My ring pack has 3 rings, but my piston only has 2 ring grooves. Did I get the wrong ring pack? Or was the piston made incorrectly?

Neither. What you have is a 2-ring piston designed to utilize the top and oil rings ONLY. Simply throw away your second ring and install as normal. NOTE: If you see a V-shaped groove below the top ring groove, that’s actually an Accumulator Groove and you can’t put a ring in it.

Q: I broke a ring during the install, can I just use OEM rings with this piston?

No, OEM rings will not fit; you would have to get another CP ring set.

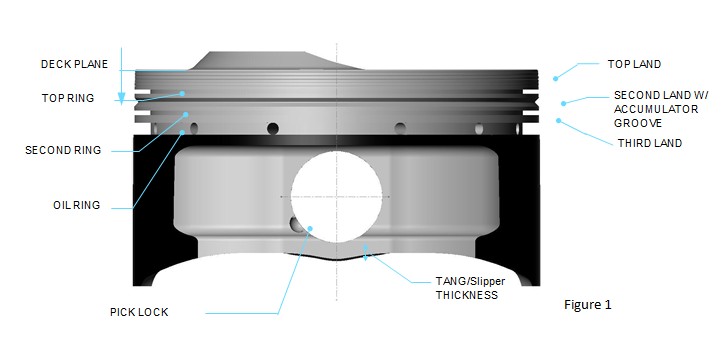

Q: How do I identify Tops, 2nds and oil rings?

See figure 1. Assuming your top and second rings are of different thicknesses you can simply measureyour rings and compare them to the groove dimensions. (SEE DRAWING) In instances where the top and second rings are of the same thickness the top ring will generally be of a shiny silver/copper color whereas the second ring will be of a dark grey or black coloring. Both rings will normally be marked with a dot(.), number, or letter that will aid in determining which side of the ring will face up toward the dome of the piston.

If the rings don’t have a dot or letter to mark “up”, check the ID of the ring and they should be beveled. The inner beveled edge of the top ring will face up towards the cylinder head, and the inner beveled edge of the second ring will face down towards the crank.

Additionally, some second rings will have a tapered hook groove on the OD. This hooked edge will face downward as its function is to scrape oil back down into the crank case. See Figure 4

In the rare instance that you receive a ring with no designation, though it could mean the ring manufacturer has determined that it will work effectively either way, we recommend that you contact us for clarification.

All of our oil rings for 4-stroke applications utilize a 3-piece design which consists of two thin oil rings separated by an expander (wavy) ring.

PLEASE NOTE: DO NOT ALTER YOUR EXPANDER. Oil ring gap specifications are for the top and bottom rails only! Oil ring expanders are designed to butt against each other and when installed along with the rails allow the ring to have the correct tension when seated in the cylinder.

You may also have a piston that requires the use of a rail support, that rail will have a dimple to prevent rotation.

Q: How do I cut ring grooves?

You don’t, we do. Attempting to alter the ring groove(s) of your CP piston could severely compromise the integrity of the part. The good news - if you have the correct rings and your piston is in good condition there should be no reason to alter the ring grooves.