The Importance of Proper Deck, Dome, and Dish Thickness

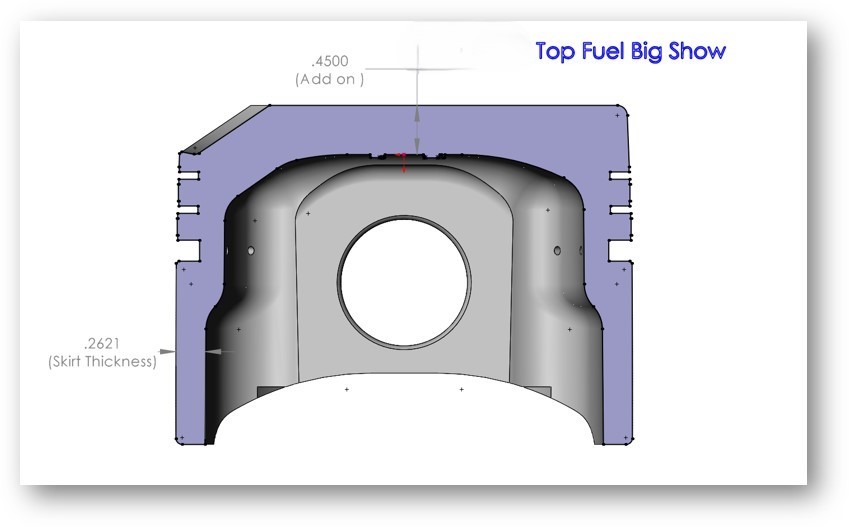

When designing pistons, it’s not just about making them thick or thin — it’s about finding the right balance for the application and the forging being used. The thickness of the deck, dome, and dish directly affects stability, strength, and weight, all of which determine how the piston performs under stress.

Some builders believe that a thinner piston can actually be beneficial:

- Weight reduction – A lighter piston assembly allows the engine to rev faster and higher.

- Controlled failure in NOS applications – In nitrous engines, a thinner piston can act like a “fuse.” If the tune-up is off and detonation occurs, the piston may fail first (burning a hole), shutting down the engine before expensive components like cylinder heads are damaged.

At CP-Carrillo, we see it differently. We engineer pistons to be thick enough to handle the power and the application while minimizing unnecessary weight. For power-adder engines, such as nitrous applications, a piston that fails because it was made too thin is not a cost savings — it’s an added expense. Beyond the piston itself, customers also face the cost of gaskets, rings, labor, and downtime for disassembly and reassembly. That’s why we discourage unsafe compromises.

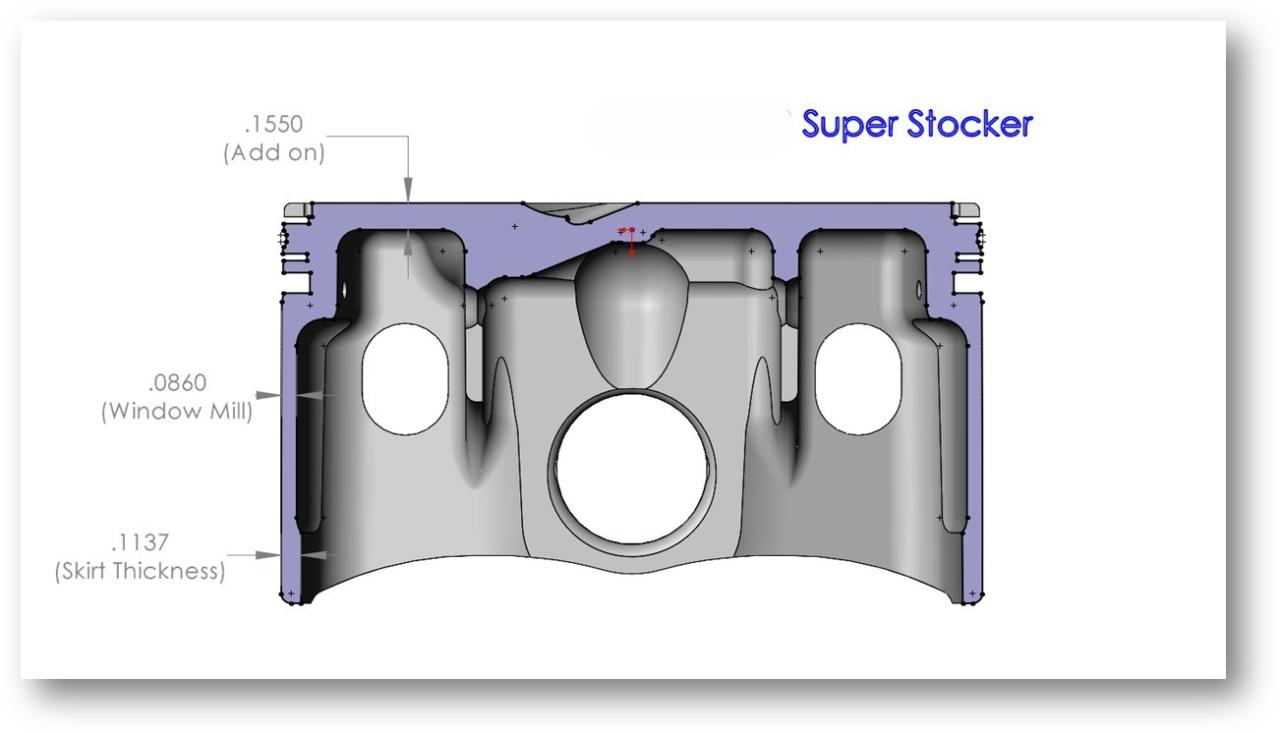

Even in naturally aspirated engines, like Super Stock builds, thickness matters. Take a flat-top piston on a round traditional forging: if the deck is made too thin, piston deflection can occur. This movement disrupts ring sealing, leading to lost power and poor reliability.

For example, our SBC 327 piston designed for 620 HP uses an inboard strut forging that provides added stability. With the correct forging, carefully engineered deck thickness, and an optimized ring pack, the entire package works together to deliver impressive, reliable power.

At CP-Carrillo, every piston is designed to meet the expected power level without adding excess weight that could throw off balance. The result is a piston that’s safe, stable, and efficients — never too thin to risk failure, never too thick to compromise performance.

The CP-Carrillo philosophy: engineer pistons strong enough for the power, light enough for performance, and never unsafe.

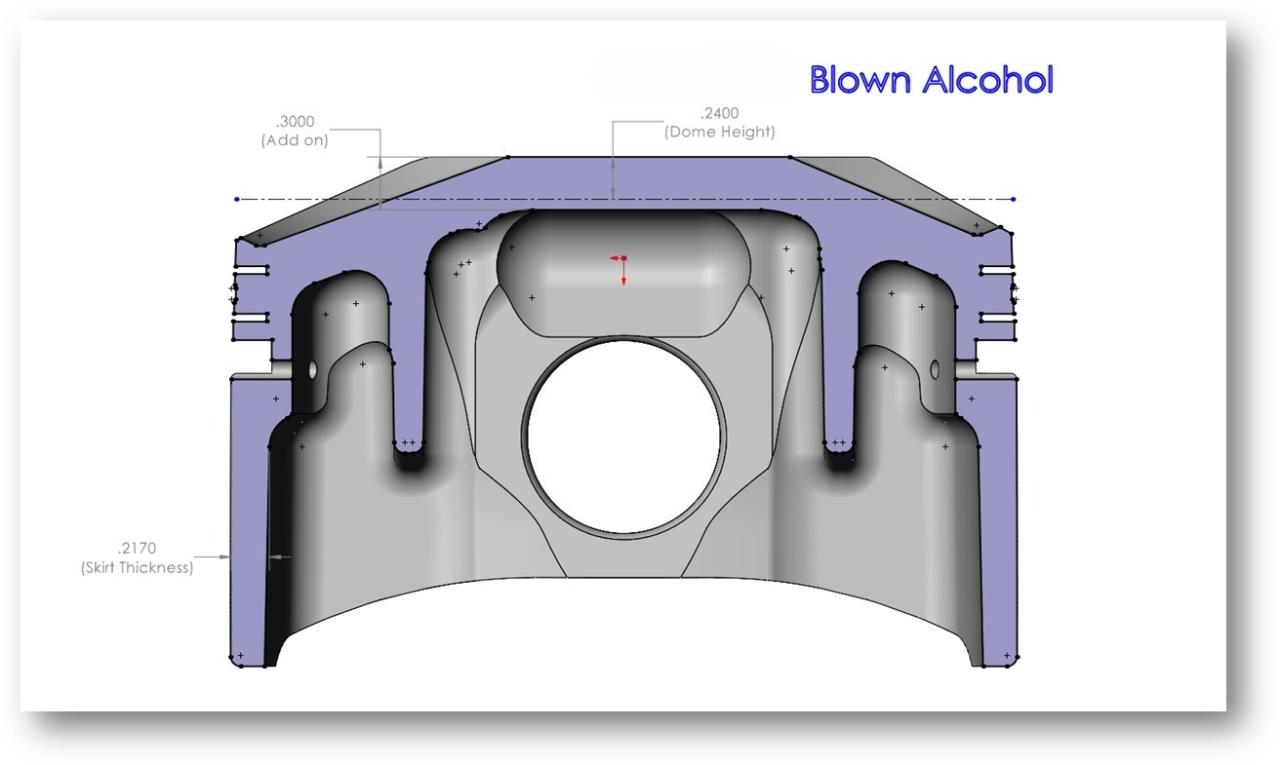

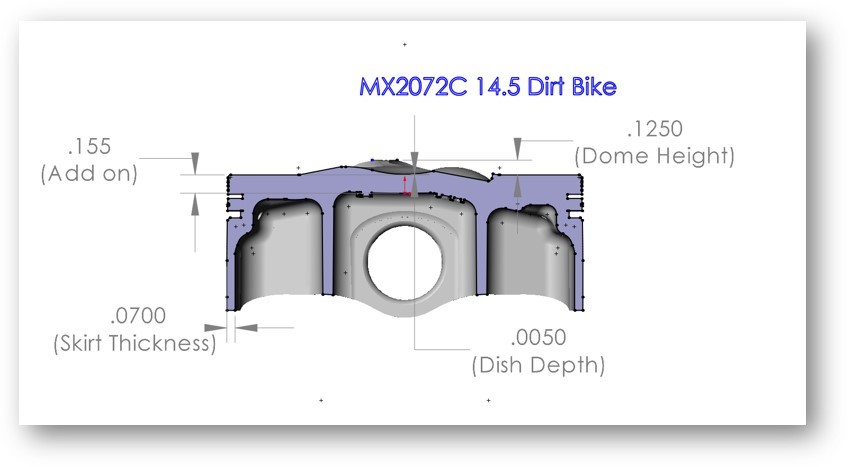

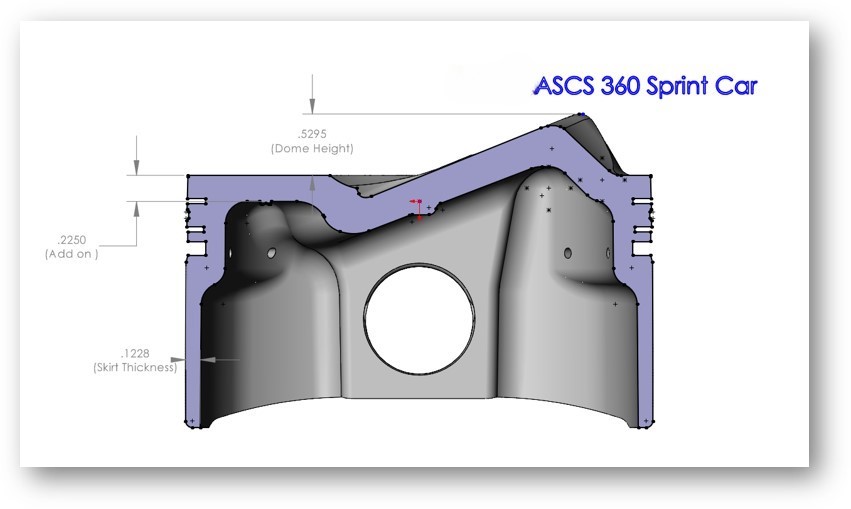

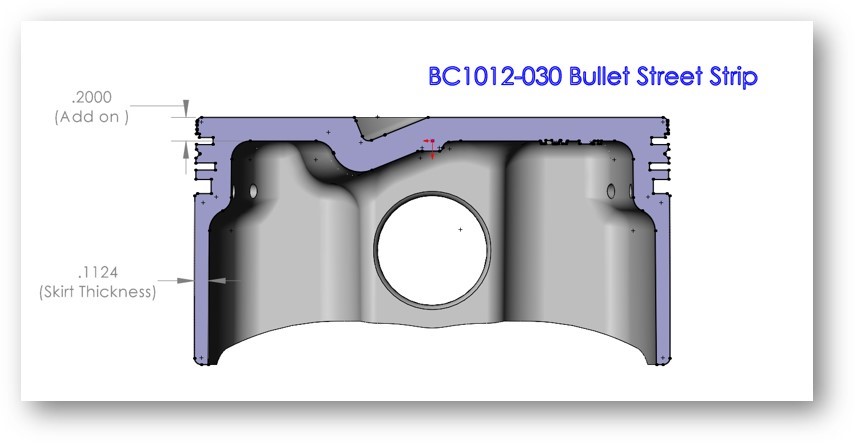

We’ve included some visual examples below to highlight different applications using a variety of forging types. Keep in mind, not every forging will have the same thickness — these illustrations are simply reference points. Each job is unique, and our engineers determine the proper thickness based on the specific details provided for that application.